IMAN GROUP

SNOL

SNOL, We began our journey in thermal process equipment market since the foundation of a laboratory electric furnace factory in a small Lithuanian town of Utena in 1960. With the first product being Laboratory muffle furnace MP-2M – our portfolio grew rapidly and today we are producing over 70 models of Laboratory furnaces and ovens and over 90 models of Industrial furnaces/ovens. In 2004 we merged with – JSC Umega group – the largest metal processing company in the Baltic States having more than 700 employees.

IMAN GROUP

PRODUCTS MADE BY SNOL

LABORATORY FURNACES

High accuracy laboratory electric furnaces with fiber-insulated chambers, that are designed for hardening, loosening, normalising and other thermal processing up to a temperature of 1100 °C or 1300 °C. The furnaces include ceramic hearth plates. To eliminate gasses or smoke that are released during thermal processing, ventilation hole and an exhaust system may be additionally installed in the products. The furnaces are an excellent fit for scientific laboratories, educational institutions, medicine and industry.

- • Muffle furnaces with fiber-insulated chambers

- • Chamber furnaces with fiber-insulated chambers

- • Furnaces with ceramic chambers

- • Ashing furnaces

- • Shaft furnaces

LABORATORY OVENS

CHAMBER OVENS UP TO 200 °C

Economical low temperature electric ovens that are designed for the thermal processing of various materials and parts up to a temperature of 200 °C. The products can be used in scientific laboratories, educational institutions, medicine and industry.

CHAMBER OVENS UP TO 300 °C

Laboratory ovens that are designed for the thermal processing of materials up to a temperature of 300 °C. Used for such processes as drying, heating, thermal testing and aging in an air environment. Forced air circulation allows a homogenous temperature distribution to be achieved during all processes, which ensures optimal results.

CHAMBER OVENS UP TO 350 °C

Economical low temperature electric ovens that are designed for the thermal processing of various materials and parts up to a temperature of 350 °C. The product can be used in scientific laboratories, educational institutions, medicine and industry.

MULTI-CHAMBER OVENS

Multi- chamber low temperature electric ovens that are designed for the thermal processing, drying, preliminary heating and other thermal processes of various materials and parts up to a temperature of 200 °C.

CHAMBER FURNACES

High-accuracy industrial electric furnaces are suitable for hardening, stress relieving, normalising, and other thermal treatment processes up to 1300 °C. Furnaces are fitted with several door opening positions and equipped with ceramic or heat resistant steel hearth plates. Vents are provided in all products for removal of escaping gas or smoke during the thermal treatment process. The furnaces can be applied in metal, and other branches of industry.

CHAMBER FURNACES WITH A REMOVABLE HEARTH

Firm structured furnaces with a removable hearth for a more comfortable loading are used for thermal processing of various types of materials up to 1300 °C. The furnaces are suitable for hardening, stress relieving, normalising, and other thermal treatment proc-esses. The furnaces may be applied in metal and other branches of industry.

CHAMBER OVENS UP TO 350 °C

Universal industrial electric furnaces / ovens with induced air circulation are suitable for various materials curing, primary heating, and other thermal treatment processes up to 350 °C. Ovens can be applied in electronics, plastics, metal, and other branches of in-dustry. The application of induced air circulation ensures an even temperature distribution throughout the chamber and enhances high-quality and fast heat treatment process.

CHAMBER OVENS UP TO 400 – 600 °C

Universal industrial electric ovens with induced air circulation are suitable for various materials curing, aging, annealing, stress re-lieving, normalising, and other thermal treatment processes up to 400 – 600 °C. Ovens can be applied in electronics, plastics, met-al, and other branches of industry. The application of induced air circulation ensures an even temperature distribution throughout the chamber and enhances high-quality and fast heat treatment process.

OVENS WITH A REMOVABLE HEARTH UP TO 600 °C

Ovens with a removable hearth for a more comfortable loading are used for thermal processing of various overall materials up to 600 °C. Ovens are suitable for curing, primary heating, annealing, stress relieving, normalising, hardening, and other thermal treat-ment processes. Ovens may be applied in electronics, plastics, metal, glass, and other branches of industry. The application of in-duced air circulation ensures an even temperature distribution throughout the chamber and enhances high-quality and fast heat treatment process.

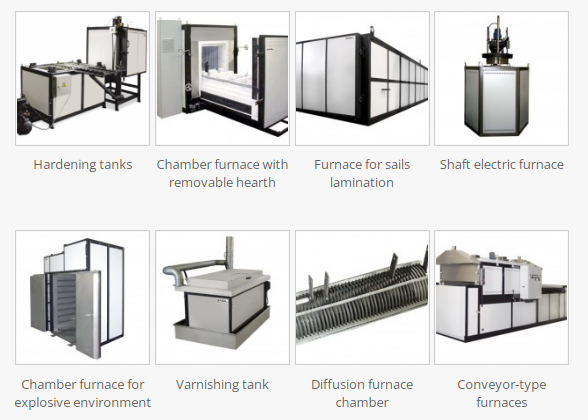

CUSTOMISED THERMAL PROCESSING EQUIPMENT DESIGNED TO CUSTOMER SPECIFICATION

The company designs and manufactures specialised technologically advanced thermal process-ing equipment of varying complexity based on customers’ requirements. A highly qualified pro-fessional team with many years experience in thermal processing equipment design and man-ufacturing, is capable of producing tailor-made technical solutions for project implementation and ensures high quality and reliability of the unit.